Excipients are essential but integral components of medicines. They perform several functions that are important for the safe use of medical products. However, there still remains a lot of ambiguity on what excipients are, their safety and if they should be removed from products, especially products intended for very young children. This article aims to answer all these and many other questions you have always had but did not who to ask or where to find answers.

What is a Pharmaceutical Excipient?

An excipient is defined as any ingredient other than the active ingredient(s) included in formulations of therapeutic goods, such as medicines, vaccines and medical devices. Excipients are also used in some cosmetic products, and nutraceutical food supplements.

In most products, excipients constitute the largest component of the formulation, being anywhere from 40 to 99+ percent by weight. This is why excipients are often referred to as ‘bulking’ agents.

If we take the example of PANADOL tablets – a commonly used pain killer medicine, each PANADOL tablet contains 500mg of paracetamol, which is the active ingredient. However, there are other ingredients in the product, as outlined below:

- maize starch

- purified talc

- stearic acid

- povidone, and,

- a film coating made from hypromellose

All the listed ingredients with the exception of paracetamol are the excipients in this product. They are typically listed in in the SmPC document (Summary Product Characteristics), which you can find by searching in a public compendia, such as the Electronic Medical Compendium.

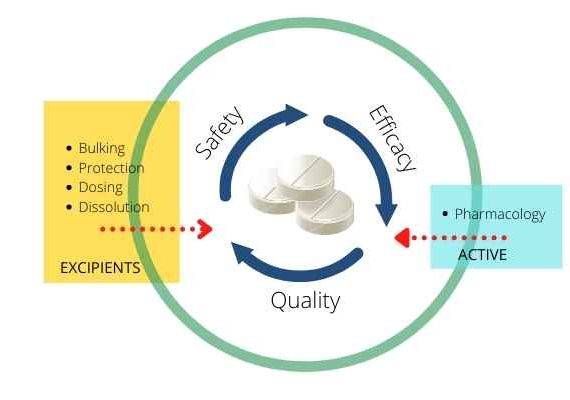

Functions of Excipients in Medicinal Products

Excipients aid processing, disintegration and dissolution in the body and help protect the drug substance against unfavourable conditions, both in vivo and in vitro.

They also provide bulk, so that the product can be easily picked by the patient and conveniently used. This can be a big challenge for elderly patients or very young children. Click here to read our article highlighting the importance of empathy in new drug development. We also recently discussed the importance of dysphagia and odynophagia (swallowing problems) and how they create health inequalities if not addressed by pharmaceutical companies, which you can read through this link.

Suffice to say all the different functions undertaken by excipients work together to permit companies such as Glaxo, Astra Zeneca or Pfizer (and many others which you can see listed here) to manufacture safe, efficacious drug products that meet the quality standards set by health authorities, such as the US Federal Drug Agency (FDA), European Medicines Agency (EMA), or the Medicines and Healthcare products Regulatory Agency, and countless others around the world.

The interrelationship between excipient functionality and the pharmacological activity of the active ingredient is illustrated in this infographic below:

Origins of the word ‘excipient’

There are several (often conflicting) opinions on the origin of the word, excipient. What seems certain is its etymological basis, which is the Latin word excipiēns, the present participle of excipere. Excipere essentially means ‘to take out’ and translates into, in the modern sense, ‘everything else other than’. Thus, we can envisage excipients as materials other than active principles, used to aid the processing, elaboration or manufacture of the medicinal, cosmetic or nutraceutical products.

Such ingredients include materials used to protect, support or enhance the product’s quality, safety, stability, availability, acceptability and identity, or enhance any other attribute that allow products to be used safely and effectively.

Are Excipients Inactive?

An important question today, at least within the excipients space, is whether excipients are inactive, that is, passive bystanders that do nothing other than to hung about in products. Some have gone as far as to say that these materials are unnecessarily added into products for marketing purposes and should be avoided by consumers. This is understandable.

We can say for certain that for the most past, excipients are inert (or correctly, intended to be biologically inert). But this is not without exceptions. Generally, natural or partly-natural excipients, many of which are part of the normal human diet, are biologically inert, that is, they do not elicit a pharmacological effect. The definition of natural and nature-inspired excipients is provided in this article, which you can read by clicking through this link.

Examples of such excipients include, but are not limited to the below:

- cellulose derivatives, such as hypromellose, microcrystalline cellulose, and ethylcellulose

- polysaccharides, including starches, sugars and sugar alcohols, acacia, and mannitol

- plant oils and derivates

Many other fully synthetic substances, such as povidone, acrylic copolymers and inorganic minerals (such as calcium carbonate and calcium phosphate) are also established as inert.

Within the pharmaceutical sector, the principal requirement for any excipient is functionality, which simply refers to fitness for a named purpose. But fitness for one use does not mean fitness for use in another, and depending on factors such as route of administration, age, patient group or dosage, a material that is fine for oral use may be hazardous when injected or inhaled.

We also know for certain that, while adverse reactions to excipients are generally rare, they still do occur, and excipients can be hazardous especially when they are not used correctly. This is why consumers are advised to always read labels and liaise with health care professionals to avoid the use of products that might contain ingredients likely to cause adverse events. Click here to read about safety assessments of excipients.

Many excipients have caused problems in paediatric and adult patients, thus the idea that excipients are inactive materials is somewhat misleading, and possibly dangerous .

Examples of well-documented, non-biologically active or ‘problem’ excipients are listed in the table below:

| Excipient name/class | Reported issues/problems | Sources |

|---|---|---|

| Sulfites | Wheezing, dyspnoea and anaphylactoid reaction | Florence A T (2010), An Introduction to Clinical Pharmaceutics, Pharm Press |

| Benzalkonium chloride | Bronchoconstriction | Florence A T (2010), An Introduction to Clinical Pharmaceutics, Pharm Press |

| Aspartame | Headaches and hypersensitivity | Several |

| Saccharin | Dermatological reactions; should be avoided in children with sulfar allergies | Several |

| Benzyl alcohol | In high concentrations, potentially lethal in neonates | Several |

| Various dyes | Cross-sensitivity, headaches, urticaria, exacerbation of asthma symptoms | Several |

| Lactose | Problematic in lactase deficient individuals | Several |

| Propylene glycol | Localised contact dermatitits when used topically, lactic acidosis after absorption | Florence A T (2010), An Introduction to Clinical Pharmaceutics, Pharm Press |

| Talc | Acute respiratory distress syndrome | US FDA |

| Tocopherol Polyethylene Glycol (TPGS) | Inhibition of P-gp mediated transport | Boman et al., J Pharm Sci (2003), 92: 1250-1261 |

| Polysorbate | Inhibition of P-gp mediated transport | Boman et al., J Pharm Sci (2003), 92: 1250-1261 |

| polyethoxylated castor oil | Inhibition of P-gp mediated transport | Boman et al., J Pharm Sci (2003), 92: 1250-1261 |

| Polyethylene glycol | Inhibition of P-gp mediated transport | Boman et al., J Pharm Sci (2003), 92: 1250-1261 |

Types of Excipients

The are many different classes of excipients as are product categories. The Handbook of Pharmaceutical Excipients, an influential reference on excipients, currently lists over 400 materials. They differ by chemical properties, function and source (mineral, natural or synthetic). They may be in the form of liquids, semi-solids, solids as well as gases.

A list of different materials classified by chemical group, function and source is shown below:

| Chemical Group | Examples |

|---|---|

| Hydrocolloid gums | Pectin, Xanthan gum, Acacia, Agar |

| Mineral clays | Bentonite, Kaolin |

| Cellulose polymers | Hypromellose, Ethylcellulose, Microcrystalline cellulose |

| Starches | Maize starch, Tapioca starch, Potato starch |

| Amino acids & Proteins | Albumin, Glycine |

| Sugars & Polysaccharides | Dextrose, Polydextrose, Fructose, Lactose |

| Vinyl polymers | Polyvinyl alcohol |

| Minerals | Calcium carbonate, Magnesium carbonate, Sodium chloride |

| Petrochemicals | Liquid paraffin |

| Silicones | Dimethicone, Cyclomethicone, Simethicone |

| Polyols | Sorbitol, Mannitol, Maltitol, Xylitol |

| Acrylic polymers | Carbomers |

| Organic & Inorganic compounds | Citric acid, Ethylparaben |

| Triglycerides, Oleochemicals & Derivatives | Glyceryl monostearate, Oleic aicd, Magnesium stearate |

| Glycols | Polyethylene glycol, Polyethylene oxide |

| Alkoxides & Silicates | Silica, Calcium silicate |

| Function | Examples |

|---|---|

| Emulsifiers & Surfactants | Sodium lauryl sulfate, Tween 80, Hydrogenated castor oil |

| Fillers & Diluents | Lactose, Microcrystalline cellulose, Maize starch, Calcium phosphate |

| Film coatings | Hypromellose, Ethylcellulose, Polyvinyl alcohol |

| Binders | Maize starch, Povidone, Sodium carmellose |

| Sweeteners & Flavours | Sucralose, Xylitol, Acesulfame K, Strawberry flavour |

| Plasticizers | Sorbitol, Triethylcitrate, Glycerine |

| Drug release modifiers | Polyethylene oxide, Hypromellose, Ethylcellulose |

| Solvents & Solubilisers | Ethanol, Cyclomethicone |

| Viscosity modifiers & Suspending agents | Xanthan gum, Sodium carmellose |

| Antioxidants & Stabilising agents | Vitamin C, Vitamin E |

| Vaccine adjuvants | Aluminium hydroxide |

| Gelling agents | Carbomers, Pectin, Carrageenan |

| Glidants, Lubricants & Anti-sticking agents | Silica, Magnesium stearate, Talc |

| Preservatives | Ethylparaben, Potassium sorbate, Benzalkonium chloride |

| Disintegrating agents | Starch, Sodium starch glycolate |

| Buffers & pH modifiers | Sodium hydrogen carbonate, Phosphoric acid |

| Excipient Source | Examples |

|---|---|

| Chemical synthesis | Sodium lauryl sulfate, Tween 80, Carbomer |

| Minerals | Talcum, Kaolin, Calcium carbonate, Sodium chloride |

| Plant derived | Maize starch, Glucose, Mannitol |

| Animal derived | Lactose, Gelatin |

| Products of fermentation | Xanthan gum |

Excipients Used in Oral Solid Products

The oral route, and specifically, oral solids (mainly tablets, capsules and powders) is the most widely used route for administration of pharmaceutical products. Some studies indicate that the oral route accounts for over 80% of all medicines administered. Here is a list of the top 20 excipients most commonly used in oral solid dose formulations, including granulation binders, diluents for tablets and capsules, disintegrants, lubricants, antiadherents, glidants, colouring agents and flavours.

| Common Name | Main Function |

|---|---|

| Alginates | Binder and disintegrating agent |

| Calcium carbonate | Filler, diluent, pigment & source of calcium. Opacifier & colorant |

| Calcium phosphate (all grades) | Filler, diluent, pigment & source of calcium |

| Gelatin | Coating agent & binder |

| Croscarmellose sodium | Disintegrating agent |

| Crospovidone | Disintegrating agent |

| Povidone (PVP) | Tablet binder |

| Silicon dioxide | Glidant |

| Sodium starch glycolate | Disintegrating agent |

| Dextrose (glucose) | Filler, diluent & binder |

| Functional & Aesthetic coatings | Aesthetics & modified drug release |

| Lactose (Spray-dried, monohydrate & anhydrous) | Filler & diluent |

| Magnesium stearate | Lubricant |

| Mannitol | Filler & diluent |

| Native & modified starches | Filler, binder & disintegrating agent |

| Sorbitol | Filler & diluent |

| Microcrystalline cellulose | Filler & dry binder |

| Sodium bicarbonate | Filler & alkalising agent |

| Hypromellose | Binder & modified-release agent |

| Sodium chloride | Diluent & tonicity agent |

Excipients Used in Oral Liquid Products

Suspensions and oral liquids are an important dosage form particularly in children and the elderly or when drug products have poor solubility or cannot be formulated into tablets or capsules.

The top 12 excipients used in pharmaceutical suspensions, including syrup or dry suspensions are shown below.

| Xanthan gum | Suspending agent and viscosity modifier |

|---|---|

| Polyethylene glycol (mainly PEG 400) | Solvent and Co-solvent |

| Carboxymethylcellulose | Suspending agent and viscosity-increasing agent |

| Flavours (mainly citrus, strawberry & vanilla) | Taste masking and flavour enhancement of bitter products |

| Glucose | Sweetener |

| Maltitol | Suspending agent & diluent |

| Sucrose | Suspending agent, viscosity modifier and sweetener |

| Ethanol | Solvent & Co-solvent |

| Sorbitol | Sweetener, Suspending agent & diluent |

| Sucralose | Taste masking and flavour enhancement of bitter products |

| Propylene glycol | Solvent & Co-solvent, flavour enhancer |

| Polysorbate | Surfactant and dispersing aid |

| Parabens (All) | Preservatives |

| Acesulfame Potassium | Sweetener |

| Sodium/Potassium Benzoate | Preservative |

Excipients Used in Topical Products

Administration of medicines through the skin is referred to as ‘transdermal drug delivery’. It has grown in importance in recent decades owing to several advantages, including:

- improved patient adherence

- convenience

- options for sustained and controlled release

- avoidance of gastric irritation, and

- avoidance of first-pass effect

Even though excipients used in topical products are not intended to be swallowed, they must be safe and comply with pharmacopoeia standards and meet expected quality standards.

A list of the top 15 commonly used topical excipients include:

| Excipient | Function |

|---|---|

| Carbomers (all) | Viscosity increasing agents, Suspending agents, Emollients & Moisturizer |

| Petrolatum & Mineral Oils | Emollient & Skin conditioner, Carrier |

| Glycerin | Moisturiser and Co-solvent |

| Glyceryl Monostearate | Emulsifier and Co-emulsifier |

| Cetostearyl Alcohol | Emollient, Skin emulsifieir & Viscosity-increasing agent |

| Polyethylene Glycol | Gelling agent, Solvent & Co-solvent |

| Parabens (Methy, Propyl & Butyl) | Preservatives |

| Tocopherol (Vitamin E) | Antioxidant & Skin conditioner |

| Dimethicone & Cyclomethicone | Emollient, Skin conditioner & Carrier |

| Waxes (Bees, Microcrystalline & Others) | Refatting & Stiffening agent |

| Vegetable Oils | Emollient & Carrier |

| Isopropyl Myristate | Emollient, Skin penetrant & Carrier |

| Glyceryl Monooleate | Bioadhesive material, Emollient & Emulsifier |

| Hard Fats | Suppository base |

| Polysorbates | Surfactants, Dispersants & Co-emulsifiers |

Excipients Used in Injectable Products

The parenteral route covers all products administered by injection directly into the body’s issues.

This class of medicines can be divided into three groups:

- injection into the skin (subcutaneous, intramuscular, & intracutaneous),

- intraveneous infusions, and,

- peridural and subarachnoid routes

Injectable products offer numerous advantages over other routes of administration, including precise and adjustable dosing, predictable bioavailability, and fast onset of action.

In acute-patient-care settings, injectable drugs are the main forms of drug administration.

Since injections introduce substances directly into the body bypassing many of the body’s defences, there are extra safeguards expected from excipients.

One of these is that they should be sterile, and if the volume of the product is large (>100ml), they should be free of pyrogens and endotoxins (fragments of bacterial cell walls).

A list of the 15 most commonly used excipients in injectable products and the roles in the formulation is below:

| Excipient name | Function |

|---|---|

| Arachis oil | Carrier & Oleaginous vehicle |

| Cresol | Preservative |

| Benzyl alcohol | Preservative |

| Dextrose (Glucose) | Bulking agent & Cryoprotectant |

| EDTA | Chelating agent |

| Ethyl oleate | Carrier and Solvent |

| Human serum albumin | Stabiliser |

| Hydrogenated castor oil | Surfactant & Solubilising agent |

| Lecithin (and other phospholipids) | Surfactant & Solubilising agent |

| Macrogol 15 Hydroxystearate | Surfactant & Solubilising agent |

| Glycerol | Co-solvent |

| Polysorbate | Surfactant & Solubilising agent |

| Polysorbates | Surfactant, Solubilising agent & Dispersant |

| Potassium or Sodium Phosphate | Buffering agent |

| Sodium chloride | Tonicity adjusting agent |

| Sodium hydroxide | PH adjusting agent |

| Sodium citrate | Buffering agent |

| Sodium metabisulfite | Preservative & Antioxidant |

| Polyethylene glycol | Solvent |

| Zinc chloride | Tonicity adjusting agent |

| Hydrochloric acid | PH adjuster |

Excipient Safety Assessment

The issue of excipient safety is a major point of contention in public discourse, and possibly one of the major sources of misinformation on medical products.

Before any material can be used in a product as an excipient, regulatory agencies require manufacturers to undertake rigorous testing and guarantee that it is safe for use.

This has not always been the case – in fact, in the early days of the pharmaceutical industry, excipients were considered pharmacologically inert and rarely regulated.

This lack of control lead to many issues, including significant harm to the public. You can listen to our podcast on this through this link.

<iframe src=”https://anchor.fm/pharmacentral/embed/episodes/Introduction-Catastrophes-that-have-helped-shape-pharmaceutical-regulation-eq9ea1″ height=”102px” width=”400px” frameborder=”0″ scrolling=”no”></iframe>

Over the years, as products have become more complex and the ingredients used in them even more elaborate, safety testing of excipients is now mandatory.

Suffice to say, regulatory agencies, such the US FDA, MHRA and EMA, have approved lists for excipients, either in form of pharmacopoeia monographs or databases (e.g IIG Database, Dictionnaire Vidal or Japanese Pharmaceutical Excipients compendium) as well as standards for manufacture (e.g Good Manufacturing Practices) and distribution/handling (Good Distribution Practices) that manufacturers must comply with.

Read about excipient safety assessment here.

The bottom-line is that the pharmaceutical industry works through multiple checks and balances to ensure that quality and safety requirements are adhered to before any material can be used in a drug product.

Frequently Asked Questions About Excipients

What criteria are used to select excipients?

The main criteria for selection of an ingredient is functionality. Examples of the different functions were outlined above, but generally include:

- maintainance of a product’s integrity (containment, stability, freedom from contamination, etc)

- making up the volume

- aiding in the release characteristics of the active ingredient

- facilitating identification, etc.

But in addition to functional suitability, the excipient must be compatible with other excipients and the active. Incompatibilities can compromise product quality and safety of users.

Thus, the most suitable excipients for the job are selected, taking care that those that are selected have a genuine function in the product.

Indeed, product manufacturers are now required to state and justify the role of excipients in the product. It is no longer acceptable to add a material that does not have a clearly established and validated function.

For example, a preservative should not be included in sterile, single-dose products, such as injections or eye drops. As a general rule, only excipients that perform a needed function are required to be included int he formulation.

Which materials can be excipients?

In the USA, only materials officially recognised in the United States Pharmacopoeia-National Formulary (USP-NF) and/or listed in the US FDA Inactive Ingredients Database (IIG Database) can be used in pharmaceutical products as excipients.

The USP-NF defines the quality requirements for excipients in form of a monograph while the IIG Database shows which material is already in use and the types of products its used in.

The Europe Union does not have a bloc-wide list of approved excipients although individual countries have compendia that list approved materials for their jurisdictions.

There is however, a European Pharmacopoeia, which has excipient monographs similar to the USP-NF.

An important question is whether materials without a monograph or those not listed in official compendia be used as excipients?

Generally, a material not officially listed in a pharmacopoeia or recognised in compendia may still be used in pharmaceutical products. In deed there are various such products, including for example, butylene glycol and several others.

However, regulatory agencies require detailed assessment and evidence of that material’s safety, toxicity and quality profile. This can be time-consuming and expensive process, and for this reason, few manufacturers dare go down this route, preferring to use established/proven materials as excipients.

Which excipients should not be used in infants?

In 2008 the EU passed Regulation 1901/2006 on medicinal products for paediatric use, following which the European Medicines Agency published recommendations for pharmaceutical formulas intended for children (0-18 years old).

A few standout excipients in this regulation include:

| Excipient | Function | Regulatory Recommendation |

|---|---|---|

| Benzyl alcohol | Preservative | Not to be given to neonates |

| Ethanol | Solvent and preservative | Best avoided in children under years old. The WHO proposes the following:Not more than 0.5% for children under 6 years old Not more than 5.0% for children between 6 and 12 years oldNot more than 10.0% for children over 12 years old |

| Propylene glycol | Solvent | Avoid in children under 4 years old |

| Colouring agents | Colouring & masking | Should be avoided in all paediatric products unless absolutely necessary. AZO dyes are banned |

Which companies manufacture excipients?

Excipient manufacturers are a diverse group of companies, from public to private, small to large. You can see our compilation of the most innovative excipient manufacturers or the size of the excipients market by following through these links. Here, we provide a selection of the most important excipient companies currently:

| Company | Country HQ | Product Focus |

|---|---|---|

| BASF | Germany | Ibuprofen, Omega-3, Polxamer 188, Hydrogenated Castor oil, Povidone & Lactose |

| Dupont | United States | Silicones & Elastomers |

| IFF | United States | Microcrystalline cellulose, Flavours and Fragrances |

| Colorcon | United States | Film coatings |

| Evonik AG | Germany | Silica, Polymers, Carbomers and Antimicrobials |

| CARGILL | United States | Carbohydrate and polysaccharides |

| Lubrizol Corporation | United States | Carbomers |

| ShinEtsu | Japan | Silicones, Cellulose polymers |

| Croda | United Kingdom | Oleochemicals |

| Gattefosse | France | Oleochemicals |

| Roquette Freires | France | Carbohydrate and polysaccharides |

| Tereos Sugars & Sweeteners | France | Carbohydrate and polysaccharides |

| JH Nanhang | China | Vinyl polymers (Povidones) |

| Solvay | France | Sodium bicarbonate |

| Asahi | Japan | Polysaccharides & microcrystalline cellulose |

| Abitec Corporation | United States | Oleochemicals |

| Angus Chemical Company | United States | Buffers and salts |

| Dow Chemical | United States | Polymers & cellulosics |

| Meggle Group | Germany | Polysaccharides & microcrystalline cellulose |

| DFE Pharma | The Netherlands | Polysaccharides & microcrystalline cellulose |

| Tate & Lyle | United Kingdom | Polysaccharides & microcrystalline cellulose |

| CP Kelco | United States | Hydrocolloids |

| Ashland | United States | Film coatings, Povidones |

| JRS Pharma | Germany | Polysaccharides & microcrystalline cellulose |

| Sasol | South Africa | Oleofins |

| Eastman Chemical Company | United States | Polymers |

| Merck KGAA | Germany | Diversified chemicals, Pigments & buffers |

| IOI Oleochemicals | Germany | Oleochemicals |

| Firmenich | Switzerland | Flavours and fragrances |

| Kerry Group | Ireland | Lactose, coatings & flavours |

| SPI Pharma | United States | ODT systems, mannitol |

| Cabot | United States | Silica |

| Budenheim | Germany | Calcium salts |

| Imerys | France | Talc, calcium salts & kaolin |

| Hallstar | United States | Oleochemicals |

| Beneo | Germany | Polysaccharides |

| Inolex | United States | Oleochemicals |

| Dr. Paul Lohmann | Germany | Calcium salts |

| Lonza AG | Switzerland | Preservatives & capsules |

| Nippon Gohsei | Japan | Polyvinyl alcohol |

| Celanese | United States | Sweeteners |

| British Sugar | United Kingdom | Sugar |

| Wacker | Germany | Silicones and silica |

| WH Grace | United States | Silica |

| Seppic | France | Film coatings |

| Novo Nordisk | Denmark | Preservatives |

| Mingtai Chemicals Co | China (Taiwan) | Microcrystalline cellulose |

| Agrana | Austria | Starch |

| Calumet | Canada | Petrochemicals |

| Nisso | Japan | Hydroxypropylcellulose |

Although PharmaCentral.com does not manufacture excipients, we have distribution arrangements and partnerships with many reputable firms. If you have any questions on any materials or would like to sample or purchase get in touch through here.

Should I avoid non-medical products that use excipients?

Since many excipients are chemically-derived industrial ingredients they may not sit well with some consumers of dietary nutraceutical products who prefer natural, eco-friendly and ‘clean’ labelled.

What’s useful to remember is that pharmaceutical excipient manufacturers mainly focus on achieving and maintaining functional performance and safety, which requires materials to undergo extra levels of processing and purification.

Ultimately, the choice to avoid dietary products with excipient-grade ingredients is down to personal choice and what people believe best suits their values and motives.

Where can I obtain more information on excipients?

There are many authoritative sites and places to get information on excipients:

- International Pharmaceutical Excipients Council (IPEC)

- The World Health Organisation

- US FDA

- The Excipients Forum

- The Handbook of Pharmaceutical Excipients

You can of course, use our own PharmaCentral Products pages – where we have monographs of the most important and commonly used excipients listed. You will find all the information you need regarding any material. And the good thing is that it is 100% free.

Cited Literature and Sources Used

To ensure our content is accurate and scientifically sound, Pharmacentral implements a strict referencing policy. We only use peer-reviewed studies and reputable academic sources and authors.

Fabiano V, Mameli C, Zuccotti GV. Paediatric pharmacology: remember the excipients. Pharmacol Res. 2011 May;63(5):362-5. Doi: 10.1016/j.phrs.2011.01.006. Epub 2011 Jan 15. PMID: 21241804.

Alison Haywood, Beverley D Glass. Pharmaceutical excipients – where do we begin? Australian Prescriber (Accessed October 2021).

Excipients – an overview (Science Direct)

Overview of pharmaceutical excipients used in tablets and capsules. (Accessed October 2021).