Opinion | What Does the Recent Pig-to-Human Kidney Transplant Mean for Tissue Therapeutics?

In a pioneering procedure, a team of surgeons at New York University Langone Health Grossman School of Medicine in New...

Polyethylene Oxide is a synthetic, high molecular weight non-ionic homopolymer of ethylene oxide, represented by the formula (CH2CH2O)n, where n is the average number of oxyethylene groups (n is >2000). It may contain silicon dioxide or other additives as antioxidants. Polyethylene Oxide is supplied as a white or off-white, free-flowing powder with a slight ammoniacal odour.

Pharmacopoeial Compliance: USP-NF; Ph.Eur; B.P; J.P; I.P

Synonyms and Trade Names: Polyethylene Oxide; Polyoxyethylene; Polyox®

Uses and Applications: Mucoadhesive Polymer; Coating Polymer Base; Tablet Binder; Thickening Agent; and Sustained-Release Polymer

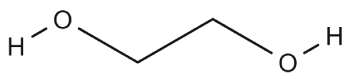

Polyethylene oxide (PEO) is a polymer prepared by polymerization reaction (polycondensation) of ethylene oxide and water catalyzed by acidic or basic catalysts. It has two chemically synonymous names: poly(ethylene glycol) (PEG) and poly(oxyethylene) (POE). PEG has tended to refer to oligomers and polymers with a molecular weight below 20,000 g/mol, PEO to polymers with a molecular weight above 20,000 g/mol, and POE to a polymer of any molecular weight with the general formula H(OCH2CH2)nOH, commercially available over a wide range of molecular weights where n is the average number of repeating oxyethylene groups (OCH2CH2) typically from 2 to few 100. The low molecular weight members from n = 2 to n = 4 are diethylene glycol, triethylene glycol, and tetraethylene glycol, respectively, which are produced as pure compounds).

The USP-NF27 describes polyethylene oxide as a non-ionic homopolymer of ethylene oxide, represented by the formula (CH2CH2O)m where n represents the average number of oxyethylene groups. It may contain up to 3% of silicon dioxide or suitable antioxidant.

Polyethylene oxide occurs as a white to off-white, free-flowing powder, with a slight ammoniacal odour.

| Chemical Name |

Poly(oxy-1,2-ethanediyl),α-hydro-ω-hydroxy- Ethane-1,2-diol, ethoxylated |

| CAS Registration Number | [25322-68-3] |

| Empirical Formula | H(OCH2CH2)nOH |

| Molecular weight | 100 000 – >7 000 000 g/mol |

| EINCES Number | 500-038-2 |

| UNII Code (FDA) | V46Y6OJ5QB (PEO 100 000) |

Polyethylene oxide is currently listed in the USP-NF. It is also included in the FDA Inactive Ingredients Database (sustained- release tablets).

| Angle of repose | 34o |

| Density (true) | 1.3 g/cm3 |

| Melting point | 65 – 70 oC |

| Moisture content | <1% |

| Solubility | Soluble in waler and a number of common organic solvents such as acetonitrile, chloroform, and methylene chloride. Insoluble in aliphatic hydrocarbons |

| Viscosity | 30 – 50 mPa s (5% aqueous solution) |

| Test | USP-NF |

| Identification | + |

| Loss on drying | 1.0 |

| Silicon dioxide and nonsilicon dioxide residue on ignition | 2.0 |

| Silicon dioxide | 3.0 |

| Heavy metals | 0.001 |

| Free ethylene oxide | 0.001 |

Polyethylene oxide is used as a mucoadhesive, coating agent, tablet binder and, occasionally, as a thickening agent.

In tablets, concentrations of 5 – 25% have been used as binders to achieve sustained-release controlled matrices. Typically, higher molecular weight grades provide delayed drug release via the hydrophilic matrix approach.

Polyethylene oxide has also been shown to facilitate coarse extrusion for tableting as well as being an aid in hot-melt extrusion.

The relationship between swelling capacity and molecular weight is a good guide when selecting products for use in immediate or sustained release matrix formulations: higher molecular weights achieve greater sustaining effects compared with lower molecular weight grades.

Polyethylene oxide has been shown to be an excellent mucoadhesive polymer.

Low levels of polyethylene oxide are effective thickener, although alcohol is usually added to water- based formulations to provide improved viscosity stability.

Polyethylene oxide films demonstrate good lubricity when wet. This property has been utilized in the development of coatings for medical devices.

Polyethylene oxide can be radiation crosslinked in solution to produce a hydrogel that can he used in wound care applications.

Polyethylene oxide polymers are nontoxic and nonimmunogenic, and approved by the US FDA as excipients. They are highly biocompatible, which makes them attractive as biomaterials. Animal studies suggest that polyethylene oxide has a low level of toxicity regardless of the route of administration. It is poorly absorbed from the gastrointestinal tract but appears to the completely and rapidly eliminated. The resins arc neither skin irritants nor sensitizers, and they do not cause eye irritation.

Store in tightly sealed containers in a cool, dry place. Avoid exposure to high temperatures as this can result in reduction in viscosity.

When handling the material, observe normal precautions appropriate on the circumstances and quantity of material handled. Polythylene oxide may form an explosive dust-air mixture. Gloves, eye protection. a respirator, and other protective clothing should be worn.

Polyethylene oxide has not yet been assessed for sustainability and environmental impact.

POLYOX™ Polyethylene Oxide

| Grade | Approx. M.W | Main application |

| POLYOX™ N-10 | 100 000 | Osmotic pump tablets & Oral thin films |

| POLYOX™ N-80 | 200 000 | Osmotic pump tablets & Oral thin films |

| POLYOX™ N-750 | 300 000 | Oral thin films, Hot melt extrusion, Abuse deterrence, and Sustained release |

| POLYOX™ 250 | 600 000 | Oral thin films, Hot melt extrusion, Abuse deterrence, and Sustained release |

| POLYOX™ 1105 | 900 000 | Oral thin films, Hot melt extrusion, Abuse deterrence, and Sustained release |

| POLYOX™ N-12K | 1 000 000 | Oral thin films, Hot melt extrusion, Abuse deterrence, and Sustained release |

| POLYOX™ N-60K | 2 000 000 | Osmotic pump tablets, Hot melt extrusion, Abuse deterrence, and Sustained release |

| POLYOX™ 301 | 4 000 000 | Oral thin films, Hot melt extrusion, Abuse deterrence, and Sustained release; Mucoadhesive & Gastroretentive |

| POLYOX™ COAGULANT | 5 000 000 | Oral thin films, Hot melt extrusion, Abuse deterrence, and Sustained release; Mucoadhesive & Gastroretentive |

| POLYOX™ 303 | 7 000 000 | Oral thin films, Hot melt extrusion, Abuse deterrence, and Sustained release; Mucoadhesive & Gastroretentive |

[2] M.M. Crowley, F. Zhang, J.J. Koleng, J.W. McGinity, Stability of polyethylene oxide in matrix tablets prepared by hot-melt extrusion, Biomaterials, 23 (2002) 4241-4248.

[4] J.D. Schulze, D.A. Ashiru, M.K. Khela, D.F. Evans, R. Patel, G.E. Parsons, M.D. Coffin, A.W. Basit, Impact of formulation excipients on human intestinal transit, The Journal of pharmacy and pharmacology, 58 (2006) 821-825.

[6] S.B. Tiwari, A.R. Rajabi-Siahboomi, Extended-release oral drug delivery technologies: monolithic matrix systems, Methods in molecular biology (Clifton, N.J.), 437 (2008) 217-243.

In a pioneering procedure, a team of surgeons at New York University Langone Health Grossman School of Medicine in New...

[bsa_pro_ad_space id=2]

[bsa_pro_ad_space id=4]

PharmaCentral.com may on occasion publish user-generated content. Any information provided on our platform is for general informational and educational purposes only. All information is provided in good faith to enable collaboration and sharing of know-how among our community of users. Authors who submit content retain copyright to it.

PharmaCentral.com does not make any representation or warranty of any kind regarding its accuracy, adequacy, or legality. Any references to particular product names, brands, descriptions, formats, styles, corporate entities, tests, applications, technologies, uses, standardisations, medical conditions, and treatments are for illustration purposes and should not be considered complete or binding. All respective intellectual property, such as trademarks and logos, are properties of their owners

Under Section 107 of the Copyright Act 1976, allowance is made for ‘Fair Use’ for purposes such as criticism, comment, news, reporting, scholarship, education, and research.

Fair use is a use permitted by copyright statute that might otherwise be infringing.

Some information contained on PharmaCentral.com may contain copyrighted material, the use of which may not have been specifically authorised by the respective copyright owners. Some material is made available to help explain and relay complex phenomena, formulae, physical and chemical constants, and other concepts that are scientifically incontestable but relevant to the use of products, and/or to illustrate, transmit, and teach pharmaceutical science principles. Some material is published to support research and user education, and for the public good.