Ammonio Methacrylate Copolymer Excipient | Uses, Suppliers, and Specifications

Description

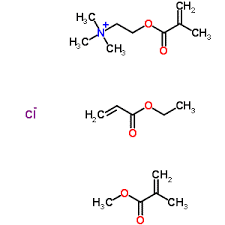

Ammonio Methcrylate Copolymer is Poly(ethyl acrylate-co-methyl methacrylate-co-trimethylammonioethyl methacrylate chloride) 1:2:0.2. The PhEur describes Ammonio Methyacrylate Copolymer as a poly(ethyl propenoate-co-methyl 2-methylproppenoate-co2-(trimethylammonio)ethyl 2-methylpropenoate) chloride having a mean relative molecular mass of about 150,000. The ratio of ethyl propenoate to methyl 2-methylpropenoate to 2—(trimethylammonio)ethyl 2-methylpropenoate is about 1:2:0.2 for Type A and 1:2:0.1 for Type B. The USP-NF describes Ammonio Methcrylate Copolymers Type A and Type B as consisting of fully polymerized and quaternary ammonium groups.

Physicochemical Properties

| Physical state | Solid (powder) |

| Alkali value | 27.5 – 31.70 (Type A)

12.1 – 18.3 (Type B) |

| Density (bulk) | 0.390 g/cm3 |

| Density (tapped) | 0.424 g/cm3 |

| Density (true) | 0.82 – 0.84 g/cm3 (Eudragit RL/RS) |

| Refractive index | index = 1.380 -1.385 |

| Solubility | Acetone & Ethanol. Swells in water and intestinal fluids |

| Viscosity (dynamic) | ≤15 mPa.s |

Applications in Pharmaceutical Formulations

Ammonio Methcrylate Copolymers are used in oral capsule and tablet formulations to form water-insoluble film coats for sustained-release products. Ammonio Methcrylate Copolymer Type A is more permeable than those of Ammonio Methcrylate Copolymer Type B, and films of varying permeability can be obtained by mixing the two types together.

The benefits of using Methacrylic acid – Methyl methacrylate Copolymer (1:2) are:

-

- pH-dependent drug release

- targeted delivery to the ileum

- wide range of actives

Pharmacopoeial Specifications

PhEur monograph

| Test | Specification | Reference |

| Identification | A, B | PhEur |

| Characters | White, free-flowing powder | PhEur |

| Appearance of a film | + | PhEur |

| Apparent viscosity | ≤15 mPa.s | PhEur |

| Ethyl acrylate and methacrylic acid | ≤100ppm | PhEur |

| Methyl methacrylate and methacrylic acid | ≤50ppm | PhEur |

| Heavy Metals | – | PhEur |

| Loss on Drying | ≤3.0% | PhEur |

| Sulphated Ash | ≤0.1% | PhEur |

| Assay (Amino methacylate units)

Type A Type B |

8.9 – 12.3% 4.5 – 7.0% |

PhEur |

USP-NF monograph

| Test | Specification | Reference |

| Identification | + | USP-NF |

| Viscosity | 15 mPa.s | USP-NF |

| Loss on drying | ≤3.0% | USP-NF |

| Residue on ignition | ≤0.5% | USP-NF |

| Heavy metals | ≤0.002% | USP-NF |

| Limit of total monomers | + | USP-NF |

| Limit of methyl methacrylate | ≤0.005% | |

| Assay (Amino methacylate units)

Type A Type B |

8.85 – 11.96% 4.48 – 6.77% |

USP-NF |

Safety and Regulatory Status

Ammonio Methcrylate Copolymer are listed in the PhEur (Ammonio Methcrylate Copolymer (Type A); Ammononio Methacylate Copolymer (Type B) and in the USP-NF (Aminoalkylmethacrylate Copolymer). It is included in the FDA Inactive Ingredients Database (oral capsules and tablets).

Based on relevant chronic oral toxicity studies in rats and conventionally calculated with a safety factor of 100, a daily intake of 2-200 mg/kg body-weight depending on the grade.

LD50 (dog, SC): 4.5g/kg

LD50 (mouse, IP: 1g/kg

LD50(mouse, oral): 5.2 g/kg

LD50(mouse SC.): 6.3g/kg

LD50 (rat. lP(: 1.33 g/kg

LD50(rat, SC): 75g/kg

Stability and Storage Conditions

Dry powder polymer forms are stable at temperatures less than30C. Above this temperature, powders tend to form clumps, although this does not affect the quality of the substance and any clumps formed can he readily broken up. Dry powders arc stable for at least 3 years if stored in a tightly closed container at less than 30C.

Dispersions are sensitive to extreme temperature and phase separation occurs below 0C. Dispersions should therefore be stored at temperatures between 5 and 25C and are stable for at least 18 months after shipping from the manufacturer’s warehouse if stored in a tightly closed container at the above conditions.

Handling Precautions

Observe normal precautions appropriate to the circumstances and quantity of material handled. Additional measures should be taken when handling organic solutions of polymethacrylates. Eye protection, gloves, and a dust mask or respirator are recommended.

The materials should be handled in a well-ventilated environment and measures should be taken to prevent dust formation.

Acute and chronic adverse effects have been observed in workers handling the related substances methyl methacrylate and poly(methyl methacrylate) (PMMA). In the UK, the workplace exposure limit for methyl methacrylate has been set at 208 mg/m3 (50ppm) long-term (8-hour TWA), and 416mg/m3 (100ppm) short-term.

References

[1] E. Industries, Eudragit RL Technical information, Online Publication.

[2] C.G. Cameron, J.W. McGinity, Controlled-Release Theophylline Tablet Formulations Containing Acrylic Resins, III. Influence of Filler Excipient, Drug Development and Industrial Pharmacy, 13 (1987) 303-318.

[3] B. Glaessl, F. Siepmann, I. Tucker, T. Rades, J. Siepmann, Deeper insight into the drug release mechanisms in Eudragit RL-based delivery systems, International journal of pharmaceutics, 389 (2010) 139-146.

[4] Y. Cuppok, S. Muschert, M. Marucci, J. Hjaertstam, F. Siepmann, A. Axelsson, J. Siepmann, Drug release mechanisms from Kollicoat SR: Eudragit NE coated pellets, International journal of pharmaceutics, 409 (2011) 30-37.

[5] V.S. Dave, R.M. Fahmy, S.W. Hoag, Investigation of the physical–mechanical properties of Eudragit® RS PO/RL PO and their mixtures with common pharmaceutical excipients, Drug development and industrial pharmacy, 39 (2013) 1113-1125.

[6] S. Thakral, N.K. Thakral, D.K. Majumdar, Eudragit®: a technology evaluation, Expert opinion on drug delivery, 10 (2013) 131-149.

[7] L.A. Felton, Aqueous polymeric coatings for pharmaceutical dosage forms, CRC Press2016.

[8] R. Wulff, C.S. Leopold, Coatings of Eudragit® RL and L-55 blends: investigations on the drug release mechanism, AAPS PharmSciTech, 17 (2016) 493-503.