What is AEROPERL® 300 Pharma Mesoporous Silica?

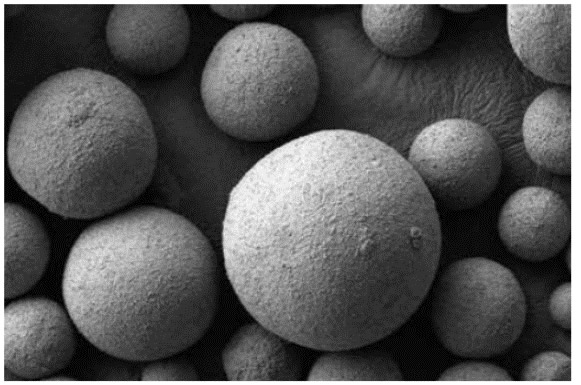

AEROPERL® 300 Pharma is a mesoporous silica obtained by granulating colloidal silicon dioxide. Mesoporous silicas are of great interest in the pharmaceutical industry due to their unique properties, such as ordered pore structures, very high internal surface areas and availability in a variety of shapes and morphologies (spheres, rods and powders).

Scanning electron micrograph of AEROPERL® 300 Pharma

Physicochemical Properties AEROPERL® 300 Pharma Mesoporous Silica

| Specific surface area (BET) m2/g | 260 – 320 |

| pH | 3.5 – 5.5 |

| Tapped density (g/l) | ≈270 |

| Average particle size (µ) | 26 – 60 |

| Pore volume (ml/g) | 1.5 – 1.9 |

| Shape | Speherical |

How is AEROPERL® 300 Pharma Mesoporous Silica used in Formulations?

Improving the Bioavailability of Poorly Water Soluble Drug Molecules

For poorly soluble active pharmaceutical ingredients (BCS II and IV) increasing the effective surface area in contact with the dissolution medium can enhance the rate of drug dissolution and improve bioavailability. This can be achieved by loading the drug substance in the form of small crystallites onto AEROPERL® 300 Pharma surface. Alternatively, the drug substance can be dissolved into a lipid carrier which is then adsorbed onto the mesoporous silica surface. Both these approaches result into a homogeneous and reproducible drug-loading and release.

Conversion of Liquid Lipid Formulations into Powders

Owing to its porous and highly adsorptive properties, AEROPERL® 300 Pharma can be used to change lipid formulations into powders. It is possible to use the material as a carrier and load it with up to 150% of its own weight with an oil without compromising its powder flow properties. This is undertaken via a simple blending process without the need for specialised equipment.

The high capillary forces draw the liquid into the pores. Moreover, this is a purely physical phenomenon, meaning that polarity of the lipid does not impact on adsorption – so provided the oil has reasonable viscosity, it will be adsorbed.

Inorganic Solid Dispersions via Solvent Evaporation Technique

AEROPERL® 300 Pharma has been investigated as an inorganic dispersion material for poorly soluble active pharmaceutical ingredients (API) in order to increase their dissolution rates. The API is first dispersed in a suitable solvent such as acetone, which is then added to AEROPERL® 300 Pharma. The acetone is then evaporated off resulting into adsorption of the API onto the surface of the mesoporous silica.

Enzyme Encapsulation into Mesoporous Silica for Biocatalysis

Owing to their pore size, pore structure and particle morphology mesoporous silica materials are of interest to many applications requiring enzymes to be immobilized or supported in situ. Immobilization of enzymes can result in enhanced stability, ease recovery and re-use, and allow the enzyme to be used in non-aqueous solvents where the enzyme is insoluble.

AEROPERL® 300 Pharma is ideally suited as a support material due to it mechanical and chemical stability as well as high surface area. It is also comparatively low cost and exhibits low non-specific protein adsorption properties. This means that adsorption of the enzyme is least likely to compromise the enzyme conformation or activity.

Moisture Activated Dry Granulation (MADG)

MADG is an approach to granulation carried out in a high shear granulator similar to conventional wet granulation except that the amount of water used is limited and there is no heat-based drying step. MADG starts with the addition of small quantities of water to a powder mix comprising the active ingredient(s), binder and other excipients, which is then blended under high shear to achieve agglomeration. The mesoporous silica, as the moisture absorbing excipient, is then added to the mixture to absorb excess moisture and to ‘dry’ the granules.

AEROPERL® 300 Pharma mesoporus silica offers an innovative approach to wet granulation processing. Studies have shown that AEROPERL® 300 Pharma serves as an efficient moisture absorber due to its high surface area and pore volume. The added moisture is bound effectively to create a stable, functional dry granular powder that can be readily processed via tabletting, capsule filling or dosing into sachets.

References

Ahern, R.J.; Hanrahan, J.P.; Tobin, J.M.: Ryan, K. B.; ,Crean, A.M.; European Journal of Pharmaceutical Sciences, 2013 50 400

Abdallah, N.H.; Schlumpberger, M.; Gaffney, D.A.; Hanrahan, J.P.; Tobin, J.M.; Magner, E.M.; J. Mol. Cat B: Enzymatic, 2014 108 82