Thinking of purchasing new pharmaceutical equipment? These are our tips on how you can minimise the global chip shortage impact on your operations.

The global chip shortage crisis is already being felt across many industries. While most of the news has focussed on the auto industry, industries ranging from medical devices to home appliances and consumer electronics are experiencing a crunch. In this article, we provide a status update on chip shortages and pharmaceutical equipment manufacturers.

The global chip shortage crisis is already being felt across many industries. While most of the news has focussed on the auto industry, industries ranging from medical devices to home appliances and consumer electronics are experiencing a crunch. In this article, we provide a status update on chip shortages and pharmaceutical equipment manufacturers.

By Emma G McConnell, Science Reporter

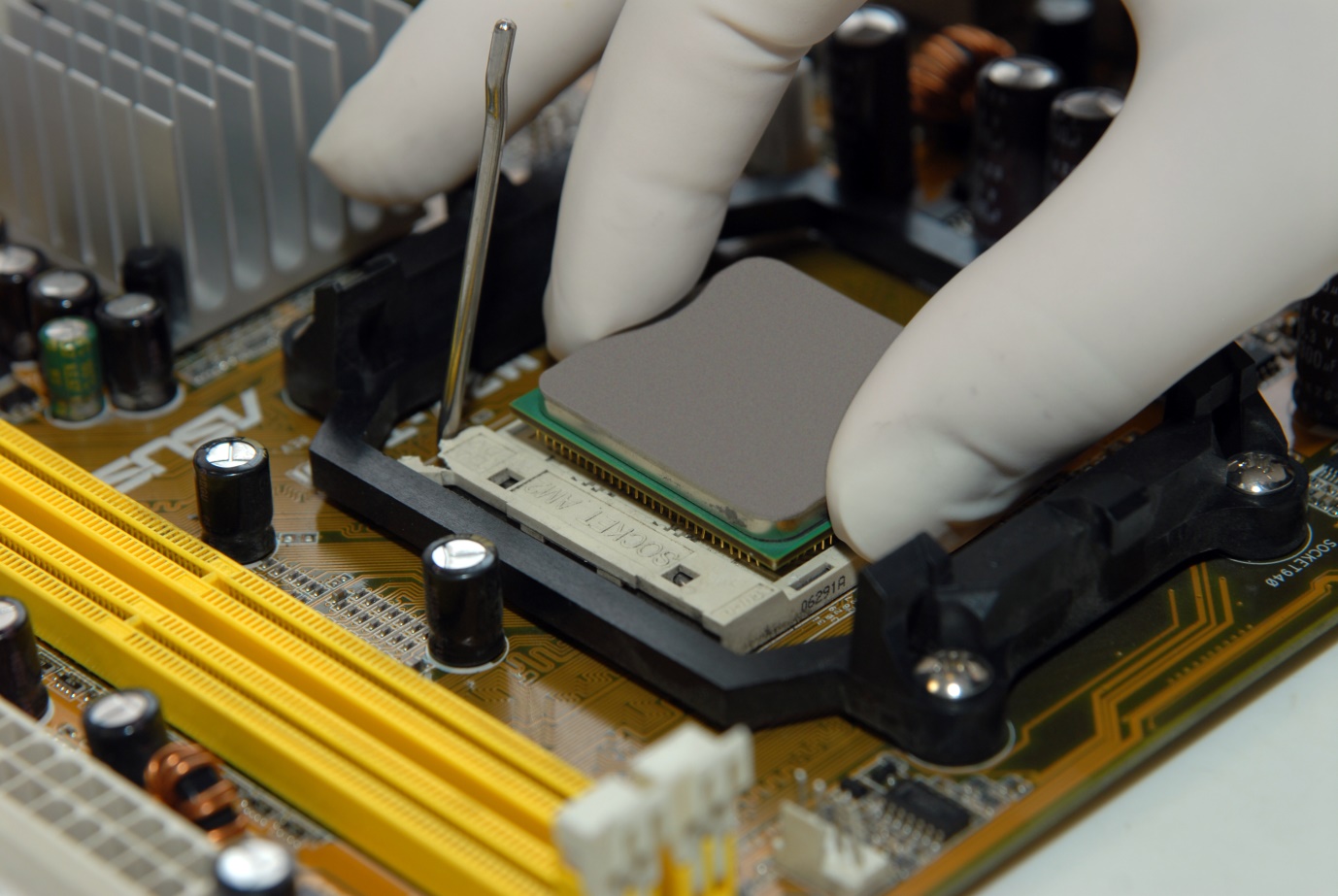

What’s driving the global semi-conductor shortage?

In a nutshell, a surge in demand from the consumer electronics industry and supply-side disruptions.

With up to 75% of global chip supply coming from Asia, some of the supply-side disruption can be tracked back to COVID-19. But the problem of chip shortages in all equipment categories (automotive, medical, home appliances, etc) we’re experiencing runs deeper than the pandemic.

The main issue is one of raw material shortage. Imagine all the devices and equipment that use chips, not just the pc or laptop or mobile device you’re using to read this but countless other smart devices. Audio, Wi-Fi chips, imaging devices, process control modules, and displays. All these compete for the same semi-conductors and materials as they rely on the same technological underpinnings. So as chip usage has grown, raw materials shortages have become an increasing problem.

A few companies have exacerbated the crisis by stockpiling chips

It has been widely reported that a few companies—for example, in China—embarked on stockpiling chips in the hope of riding out the chip shortages. Unfortunately, this action has only compounded shortfalls, making it difficult for other equipment manufacturers to get in chips they require.

“Pharma equipment manufacturers are have reported no supply disruption”

“Pharma equipment manufacturers are have reported no supply disruption”

What are the long-term consequences of chip shortages?

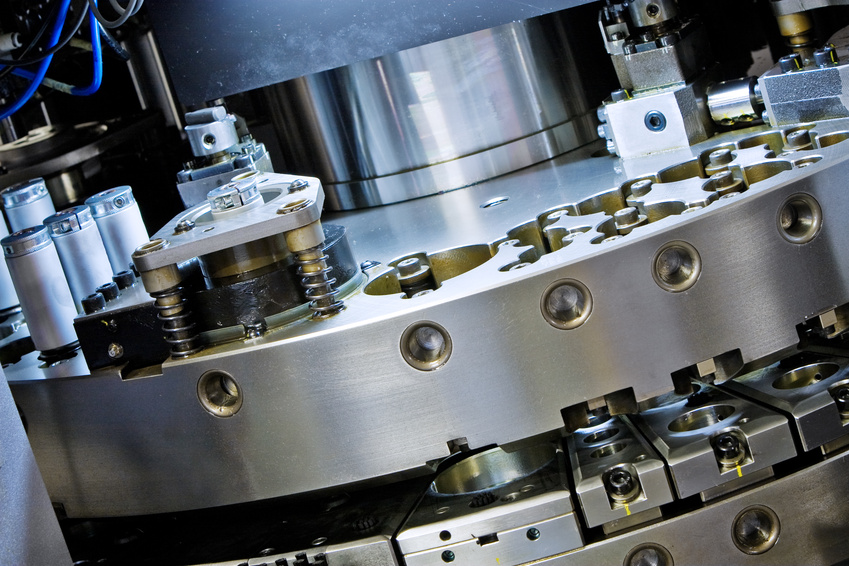

The good thing is manufacturers of pharmaceutical equipment have been aware of microchip shortages and have been exploring ways to avert any potential disruptions. All the companies we recently spoke to, including IMA, GEA and Agilent said they were not experiencing supply disruptions and delays. A sales manager at Freund Vector echoed the same sentiment when asked by PharmaCentral.

Things may be different with other companies so it’s important to assess how microchips are relevant to the company and how shortages may affect you as an equipment buyer. Speak to sales managers and ask them to confirm whether you may expect:

- Longer wait times to have orders fulfilled and shipped

- Specific brands shortages meaning that you may have to select alternative brand or model

- Price increases

For now, the message we’re getting is that there’s no need to panic, even though many experts believe the impact may carry into 2022.

As a buyer of equipment, what practical steps can you take to mitigate the impact of pharmaceutical equipment microchip shortages?

PharmaCentral recommends several proactive steps you can take today to help minimize the potential impact of chip shortages and manage challenges.

- Plan well ahead

The number-one recommendation for buyers of pharmaceutical equipment is to plan ahead. If you expect needing equipment within the next 6 to 12 months, consider ordering it now—so you’re at the front of the line as companies work through their production backlog.

It is advisable to take time assessing whether you need to acquire new technology as part of your ongoing hardware lifecycle management, perhaps to support projected growth, or to have inventory on hand to replace non-functioning equipment. This prevents having to compromise or troubleshoot around a long-term delays .

- Factor in some delays

Even if you place an order now, fulfilment times may be longer than expected. So it’s advisable to plan for delays. Communicate with your vendor to have visibility of timelines, and manage expectations with your stakeholders accordingly.

- Be flexible

As a company or individual buyer, you may have a preference for specific brand or model of equipment. This is understandable. However, you should be open to being flexible if the brand or model of equipment you always buy is on backorder. Consider other brands and models even if they are not the exact model or brand you are familiar with so as to minimise disruptions.

- Evaluate other options

Purchasing hardware isn’t always the only option. Remember, the main reason for acquiring equipment is to support a specific process or objective. This business objective can be supported through leasing or outsourcing. The decision should be based on detailed assessment of requirements and all options carefully costed.

While pharmaceutical equipment chip shortages are yet to be felt, the global crisis will likely linger a little longer. It is likely that pharmaceutical equipment buyers will see some impact over the next several months. The message, though, is that if you’re looking to buy equipment, there is no need to panic. Be proactive, flexible, and think strategically ahead.