Carbomers are an important group of excipients that every well-meaning formulator should become familiar with. Here is a quick run-through of what they are, uses and formulation tips.

Chemistry and Physical Description

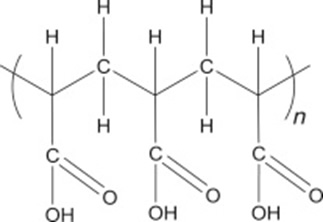

Carbomers are synthetic, chemically related, high molecular weight, nonlinear polymers based on crosslinked acrylic acid chemistry.

Originally developed by BF Goodrich and trademarked CARBOPOL® in 1958. These materials (especially, Carbopol 940, 941, and 934) revolutionised topical products by enabling formulators to create new types of product previously not possible.

The general chemical structure of carbomers is shown below:

Key Physicochemical Properties

- Molecular weight 700 kDa to 4 000 000 kDa

- Hygroscopic

- Powdered carbomers have a dry particle agglomerated size of 2-7µm.

- Do not dissolve but swell in ethanol, water, propylene glycol and glycerin to form microgels.

- Dispersions are acidic with a pH ~3. Upon neutralization (pH 7), particles swell to around 1000 times their initial volume and the viscosity dramatically increases due to charge repulsion.

- Can produce clear gels in water and ethanol due to refractive index matching.

- Highly crosslinked carbomers are commonly used as super absorbers in disposable diapers.

- Salts can decrease viscosity by reducing the charge repulsion.

Applications

- Carbomers are listed in the USP-NF, PhEur, BP; JP, IP and ChP.

- Grades with residual benzene content > 2 ppm do not meet the specifications of current pharmacopoeia monographs.

- Carbomers with low residuals of other solvents other than the ICH-defined Class 1 – 2 solvents may he used in Europe.

- Carbomers with low residuals of ethyl acetate, such as Carbopol 971P NF, are permitted for use in oral preparations, e.g suspensions, capsules or tablets.

- For topical products, carbomers can be used as gelling agents (0.1 – 2.0%), controlled-release agents (5 – 30.0%), emulsifying agents (0.5 – 1.0%), emulsion stabilizers (1.0%), rheology modifiers (0.5 – 1.0%) and stabilizing and suspending gents (0.5 – 1.0%).

- Carbomers are also employed as emulsifying agents in the preparation of oil-in-water emulsions for external administration.

- Carbomers can be used as bioadhesive polymers (0.1 – 0.5%), tablet binders (0.75 – 3.0%) and controlled release agents.

- Carbomers can aTopical medical devices (Ultrasound adhesive gel and personal and medical lubricants, and artificial tears)

Advantages

- Versatile and multifunctional excipients for oral (solid and liquids) and topical formulations.

- Synthetically derived, hence free from irregularities of natural products.

- Available in multiple grades and properties to meet different formulation or product performance requirements.

- Highly efficient thickeners at very low levels (<1% polymer). Suspensions and emulsions are efficiently stabilised due to the high yield value gels.

- Can make aqueous or alcoholic clear gels.

- Can make emulsifier free oil in water crème gel formulations.

- Can make stable water in oil in water emulsions.

- Excellent skin feel (<.5%) and shear thinning rheology.

Formulating Tips

Picture credits: Silverson FLASHBLEND Mixer

- Lightly cross-linked carbomers (lower viscosity) are more efficient at controlling drug release compared with highly cross-linked carbomers (higher viscosity).

- If used in wet granulation processes, water, solvents or their mixtures can be used as the granulating fluid. To control tackiness of the wet mass include talc in the formulation.

- Carbomers from different manufacturers or grades produced via different manufacturing processes may not have identical properties. Therefore, grades should not be interchanged without performance equivalency ascertainment.

- When preparing carbomer gels, powders should first be dispersed into vigorously stirred water, taking care to avoid the formation of agglomerates.

- The dispersion should then neutralized by the addition of a suitable base.

- Use granulated grades to reduce dusting issues during manufacturing.

- Carbomers can easily be added to emulsions by addition to the oil phase prior to emulsification.

- Adding electrolyte or small amounts of acid to the water phase prior to Carbomer addition significantly improves its dispersion by reducing solution viscosity. Up to 5% dispersions of Carbomer in water can typically be made with this approach.

- Agitation of the dispersion should be done carefully and gently with a broad, paddle-like stirrer to avoid introducing air bubbles.

- The viscosity of gels is significantly reduced at pH values less than 3 or greater 9, or in the presence of strong electrolytes.

- Suitable neutralising agents include amino acids, potassium hydroxide, sodium bicarbonate, sodium hydroxide, and organic amines such as triethanolamine.

- One gram of carbomer is neutralized by approximately 0.4 g of sodium hydroxide.

- A number of manufacturers have introduced grades to overcome the challenges of dispersing powders in aqueous solvents, e.g Lubrizol’s Carbopol Ultrez.

- Gels rapidly lose viscosity on exposure to UV light. To minimise this add a suitable antioxidant.

Leading Manufacturers of Carbomer Excipients

- Lubrizol

- Ashland

- Corel Pharma Chem

Recommended Carbomers for Pharmaceutical Formulations

- Ultrez 30 (Lubrizol) has been shown to exhibit better electrolyte tolerance than other grades of Carbomer.

- Ultrez 10 (Lubrizol) is a universal carbomer for broad applications. A 5% dispersion of Ultrez 10 exhibits viscosities in the 50 – 55 MPa s range.